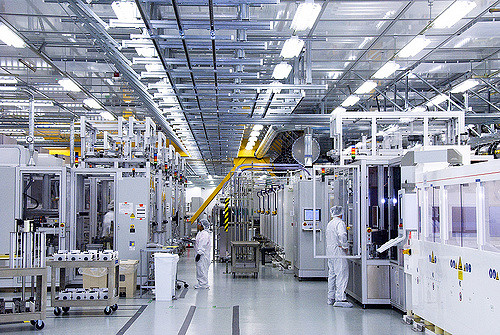

ERP frameworks settle various difficulties and give precious advantages to makers trying to diminish costs, oversee development, and streamline procedures and addition an upper hand. ERP software for manufacturing industry coordinates all ranges of business (materials and stock, creation, operations and deals, bookkeeping and account, and so on.) so that each business capacity depends on a solitary database. This “data centre” conveys precise, constant data significant to the assembling business.

Here are the top reasons today’s products require a manufacturing erp software:

- Streamline Processes. As producers develop, their operations turn out to be increasingly mind boggling. ERP producing programming robotizes all business operations, giving exact, continuous data. ERP expands proficiency and efficiency by helping clients explore complex procedures, anticipating information re-entry, and enhancing capacities, for example, creation, request culmination and conveyance.

- Taken a toll Reductions. With one wellspring of precise, ongoing data, ERP programming lessens authoritative and operations costs. It permits makers to proactively oversee operations, avoids disturbances and postponements, separates data logjams and helps clients settle on choices all the more rapidly.

- Current ERP programming frameworks are vigorous, adaptable and configurable. They are not a one-size-fits-all suggestion, but rather can be customized around the needs of a business. ERP frameworks likewise can adjust with the regularly changing necessities of a developing business.

- ERP frameworks may require a venture, but at the same time there’s an expense to do nothing. Makers can’t stand to put off an ERP execution while their opposition puts resources into ERP and begins profiting.

Manufacturing/Producing firms need to address a few key vital issues on the off chance that they need to effectively contend in this progressively changing business environment. The Worldwide focused weights putting a solid weight on makers to reduce item cost and in the meantime apply weight to essentially enhance item quality and every other part of client administrations. A typical procedure utilized by firms for accomplishing this objective is to fundamentally fix all parts of the assembling procedure, which incorporates coordination techniques, for example, in the nick of time and quality change programs.

Another key vital issue is the configuration of the item for manufacturability. This includes framing incorporated configuration groups, pulling together item plan, designing and assembling. This procedure likewise should be remembered about – Reducing request to-conveyance process duration. High level off after – deals client support for upkeep Shorter outline and process duration; Globally organized adaptable assembling and Globally planned innovative work.In this manner the nearness of a viable ERP framework is required to effectively execute the above systems.